The patented Unterland Compact film from Coveris avoids some of the serious disadvantages of pre-stretched films and is therefore the ideal net replacement for round bale grass silage. The pre-stretching of conventional wrapping films results in increased strength in the running direction. Although this reduces constriction and improves edge coverage, it also leads to more frequent splicing in the longitudinal direction. The strength of the film can easily lead to holes forming in coarse-stemmed grass and to the casing film bursting open during transport and storage.

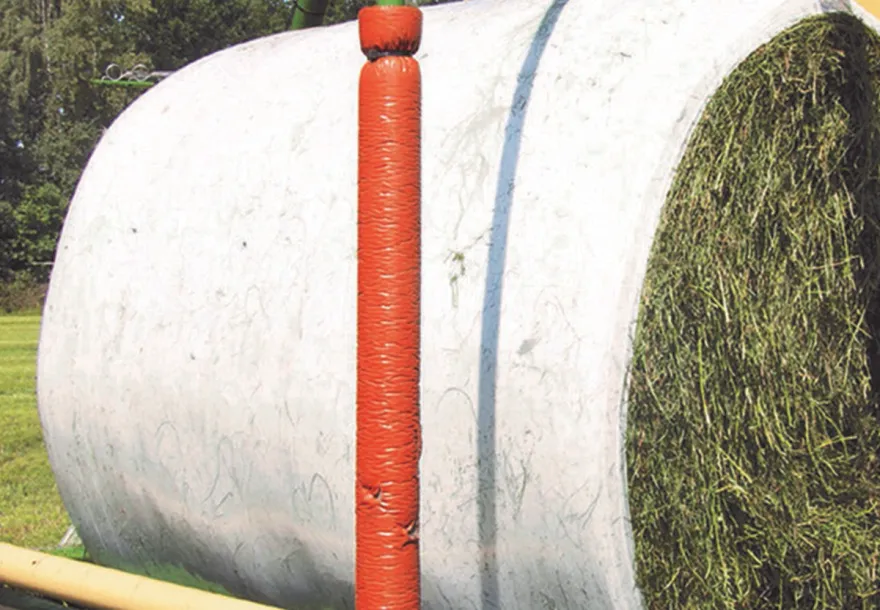

The patented quality of the Unterland Compact net replacement film from Coveris is characterised by its extremely high puncture resistance and stretchability. The resulting high tensile strength makes the bales more compact and firmer, which in turn promotes stability during transport and storage and significantly reduces the typical hole formation. ‘The additional layers of film result in a better oxygen barrier, which optimises the ensiling process. Expensive feed losses due to mould formation can be significantly reduced as a result,’ explains Martin Wildinger, Sales Manager for agricultural films at Coveris.

The use of net replacement film prevents net residues in the bale, which can jeopardise animal health. Frozen bales are easier to open.

The combined use of wrapping film and net replacement products eliminates the need to separate waste for disposal. Thanks to the standardised material of the Unterland Compact net replacement films and the wrapping films, they can be recycled together. This saves time and protects the environment.