Pioneering Circularity in Healthcare Packaging

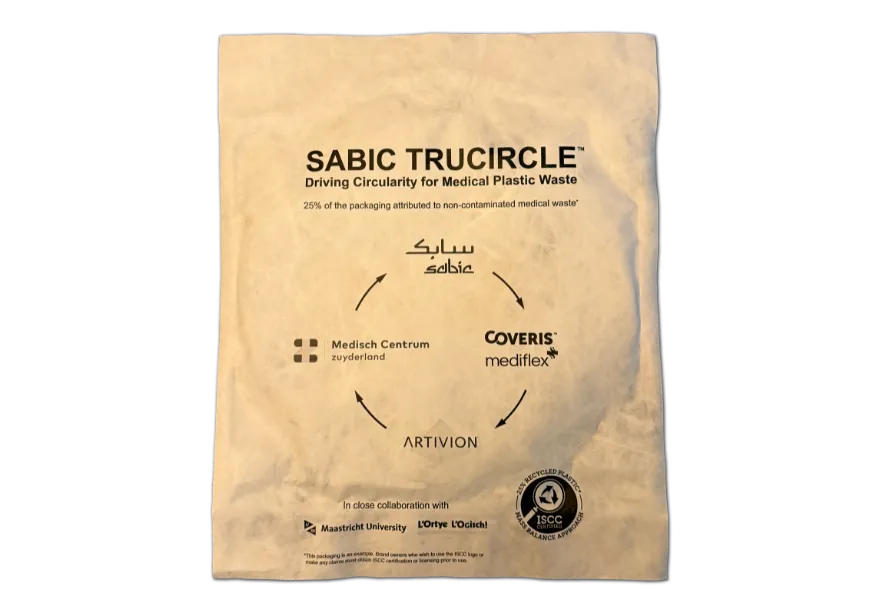

Welcome to a breakthrough moment in sustainable healthcare. Coveris, in partnership with SABIC, Zuyderland Medical Center and healthcare brand Artivion, has pioneered the first closed-loop recycling model for medical packaging, turning non-contaminated hospital waste into new, sterile packaging solutions.

Together we have successfully demonstrated that circularity in medical packaging is indeed possible. Within SABIC’S TRUCIRCLE™ initiative, a ground-breaking model for transforming hospital waste back into high-quality, contact-sensitive packaging was born – marking the first closed-loop healthcare packaging initiative of its kind.

Contact Us

Want to learn more about our circular healthcare packaging solution?

Contact us and our team will get back to you with more information about the project, its technology, and how you can be part of driving circularity in medical packaging.